Owing to our vast experience Pure Copper Earthing Electrode, we are engaged in providing excellent quality range of chemical earthing electrode to our reputed clients. This is tested by our quality controllers in order to dispatch.

Owing to our vast experience with Pure Copper Earthing Electrode, we are engaged in providing an excellent quality range of chemical earthing electrodes to our reputed clients.

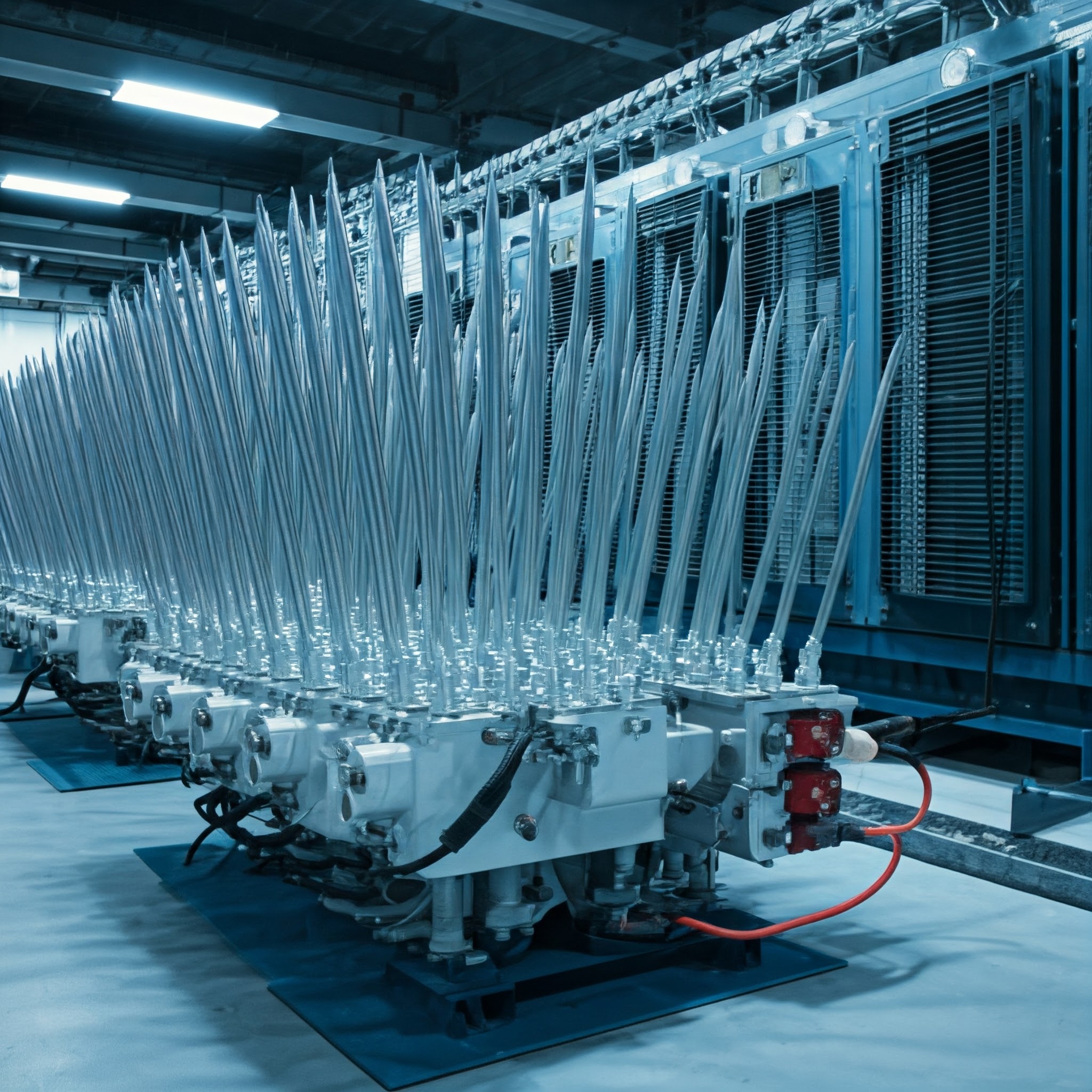

Engines prime movers and exhaust gas turbochargers.

| Model | Length (Mtr) | Dia (Available) (MM) | MM Cu |

|---|---|---|---|

| 3000 MM Cu | 3 | 40 | 50 |

| 2000 MM Cu | 2 | 40 | 50 |

| 1500 MM Cu | 1.5 | 40 | 50 |

| 1000 MM Cu | 1 | 40 | 50 |